Lots of rain in Iowa lately. Lots of flooding also. In Council Bluffs, it’s not rare to see people emptying crap out of their basements after a good rain. Here is a shot from my backyard security camera from just last week.

So while I avoid a flooded basement for the most part, I have leaks of the wazoo. I have had the unfortunate pleasure of having either my sump pump floater getting stuck or simply failing which results in more than a few puddles of water. I am sick of having to worry if something is going to go wrong when I am sleeping or when I forget to check the basement so I built a simple water level detector with a water level sensor.

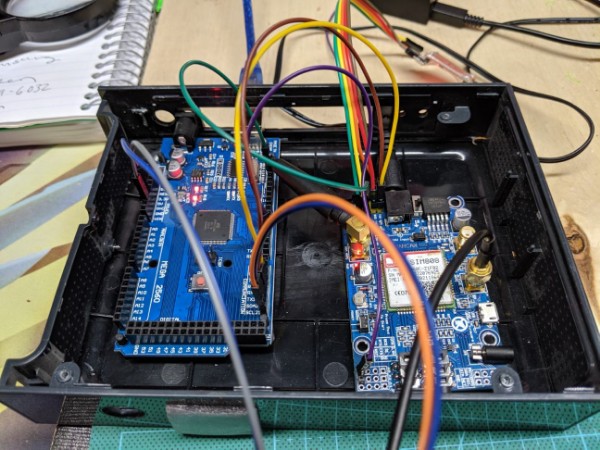

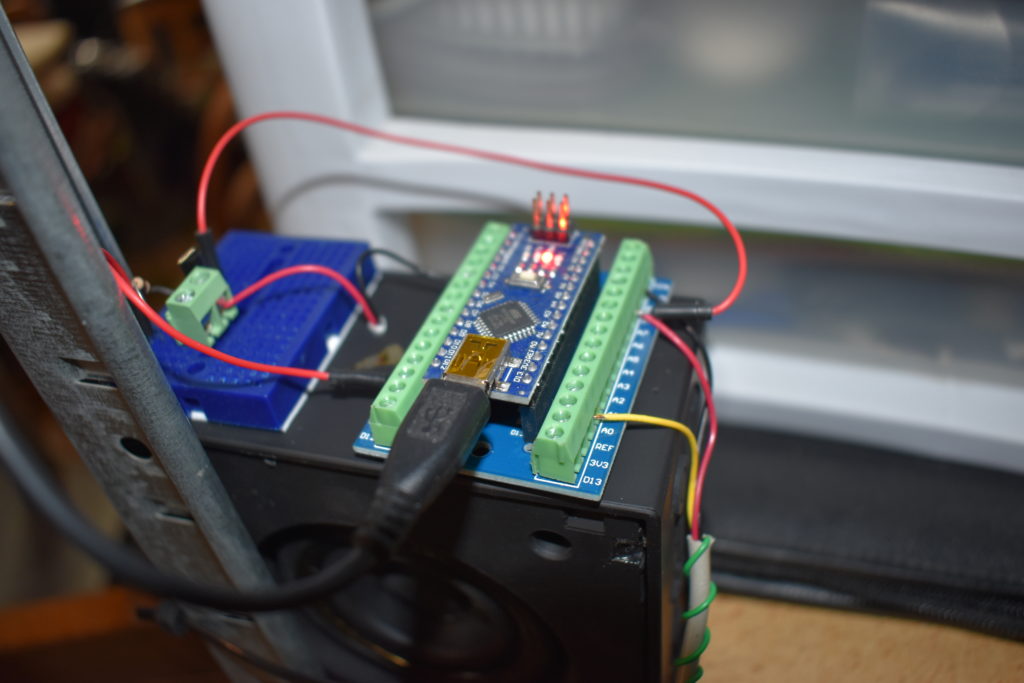

Using an Arduino Nano microcontroller and some other parts I created something that would set off an alarm if the water got too close to the top of my sump.

Parts List

- BC547 Transistor

- 100 ohm resistor

- Arduino Nano

- Funduino Water Level Sensor

- Salvaged 3 ohm speaker

After wiring up the water sensor and checking on a serial monitor what the analog value would be when water first touches the sensor and what value when water is dripping off of it I programmed the Nano to set off a nice loud alarm.

Arduino’s only put out 5 v at their output and that results in a ridiculously quiet alarm which is why I put a cheap transistor into the circuit. The result is something I can hear from upstairs and would probably wake me up at night.